3D PRINTING:

Additive manufacturing is another name for 3D printing. 3D printing is a digital model in three dimensions. The X, Y, and Z axes are the three axes that are used to describe a printer’s movements in 3D printing. To comprehend and construct, three-dimensional printing is converted into two-dimensional series of layers. The reason for this procedure is that 3D printers operate layer by layer, with each layer being essential to the creation of the final 3D object. Many different businesses and applications use 3D printing because it can create sophisticated, customised products.

Contents

The fundamentals of 3D printing technology:

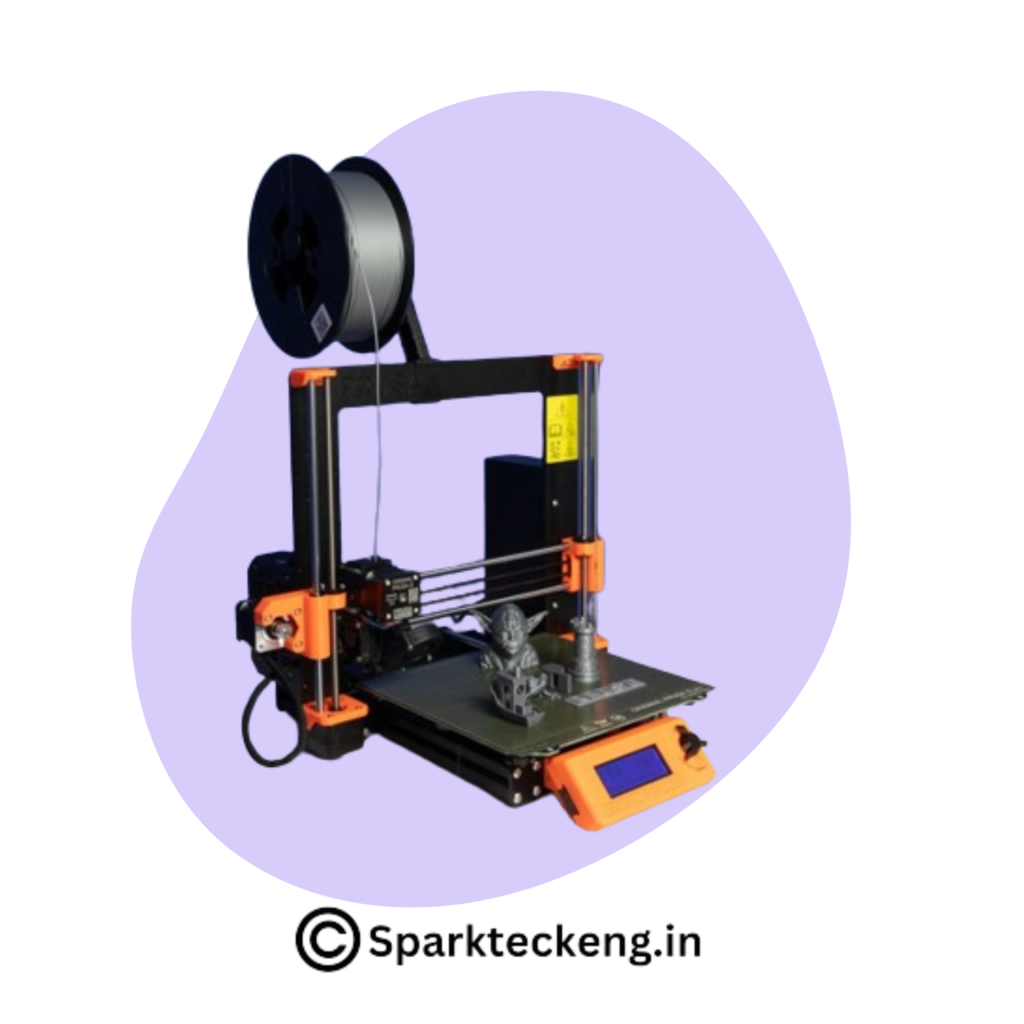

It’s essential to emphasize that the printer is the backbone of 3D printing technology. Without it, the process wouldn’t be possible. Let’s get started and explore the exciting world of 3D printing:

1. Selective Laser Sintering (SLS): SLS is a technique that combines powdered materials such as ceramic, metal, or plastic layer by layer using a laser. Materials like nylon, polystyrene, metals like aluminium, etc. are frequently utilised in SLS.

2. Fused Deposition Modelling (FDM): FDM constructs structural designs by pushing polymeric material fibres out of a moving nozzle. Materials like PETG, PLA, ABS, and others are frequently used in FDM.

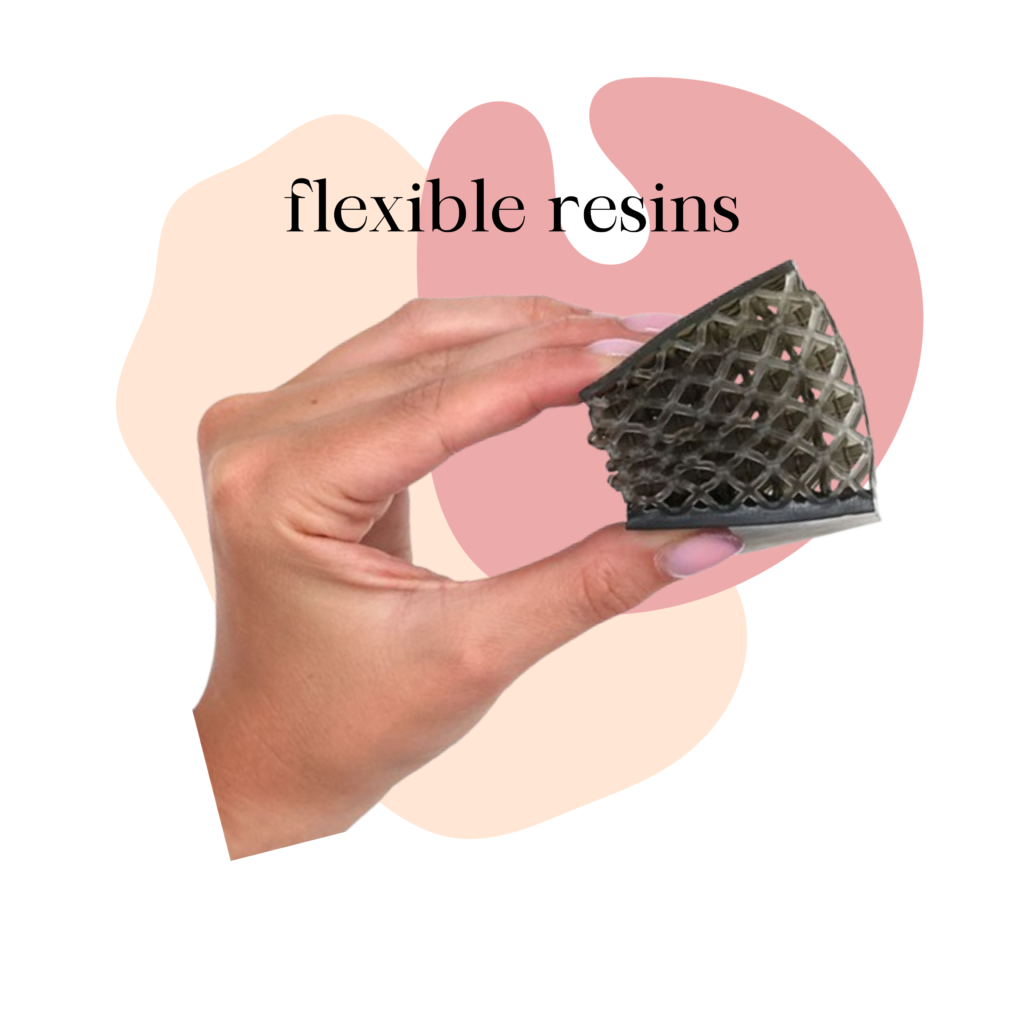

3. Stereolithography (SLA): SLA is a sophisticated kind of 3D printing. These printers cure a tiny portion of resin mostly with lasers. Resins are frequently used materials in SLA. Resins come in several varieties, such as conventional, flexible, and dental resins.

4. Digital Light Processing (DLP): This technique uses digital light to cure layers simultaneously, much like SLA.

TYPES OF 3D PRINTING MATERIAL:

There are many different kinds of 3D printers in the market, and they can print with metal, carbon fibre, resins, plastic, powder, or powder. Let’s take a closer look at the materials used in 3D printing:-

1. RESINS: Reels are either used less or have fewer applications than other materials. The most common types of resins are transparent, white, and black, while some can also be printed in orange, red, blue, and green. Printed items are less flexible and weaker than other sorts, in comparison. There are various types of resins. Standard Resins: They are used for many different things.

a. flexible Resins: These produce elastic and flexible prints.

b. Transparent Resins: They yield transparent or translucent prints.

2. PLASTICS: This raw material is used more frequently than the others. There is a wide variety of polymers available. Because of their smoothness, flexibility, and range of colours, plastic materials are easy to utilise. Polymer materials are less expensive than other materials. Plastic products are flexible and offer a wide range of printing options. Polylactic acid (PLA), polyvinyl alcohol plastic (PVA), and acrylonitrile butadiene styrene (ABS) are three examples of the different types of plastic polymers.

3. POWDER: Powders make up the majority of materials utilised in printers these days. In the printer, powder material is melted and then applied in layers until the required materials are moulded into the required shape. When metals are in powder form, it is well known that they may be easily moulded and given the required shape.

4. METALS: This is the procedure used to make metal items. But instead of shaping the object with tools, we build it layer by layer. A computer and an unusual gadget are used to achieve this.

In the vast and diverse 3D printer market, it can be challenging to find the right fit for your needs. However, with careful analysis and adherence to the principles mentioned in this guide, you can confidently make an informed decision that meets your individual requirements. So take control and navigate the options available with confidence.

Add a Comment